Our Product

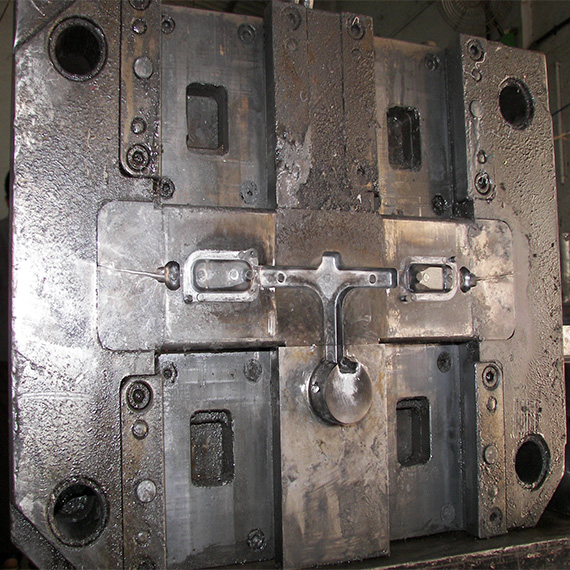

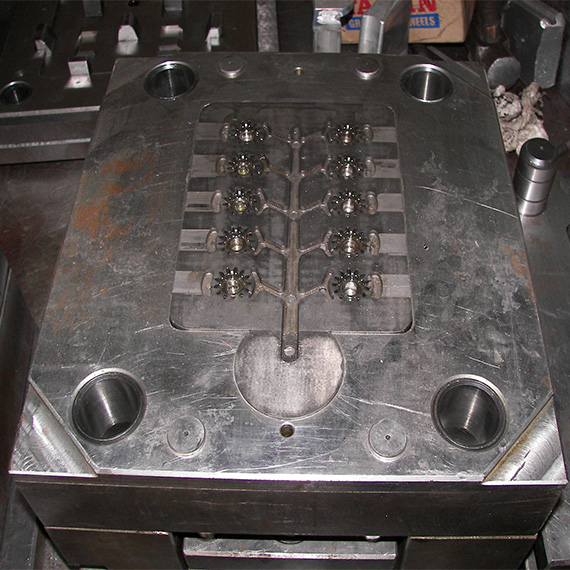

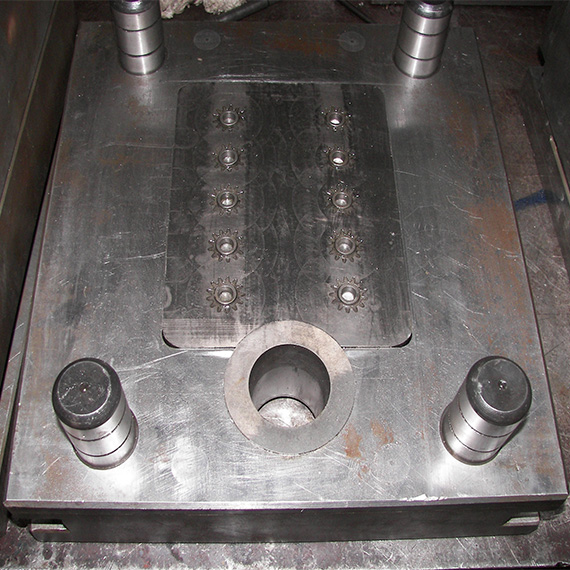

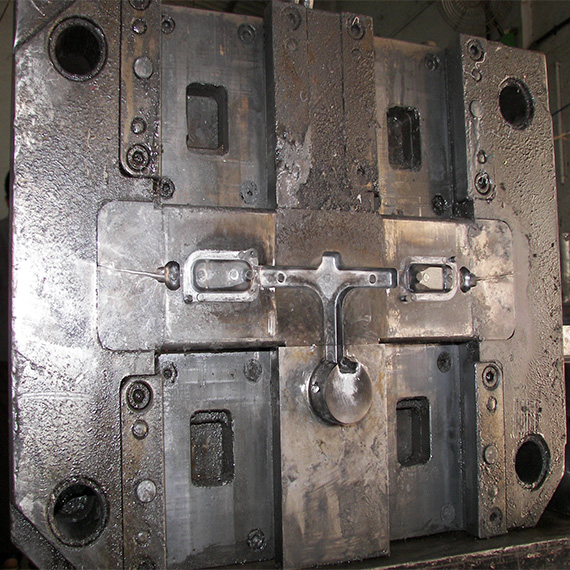

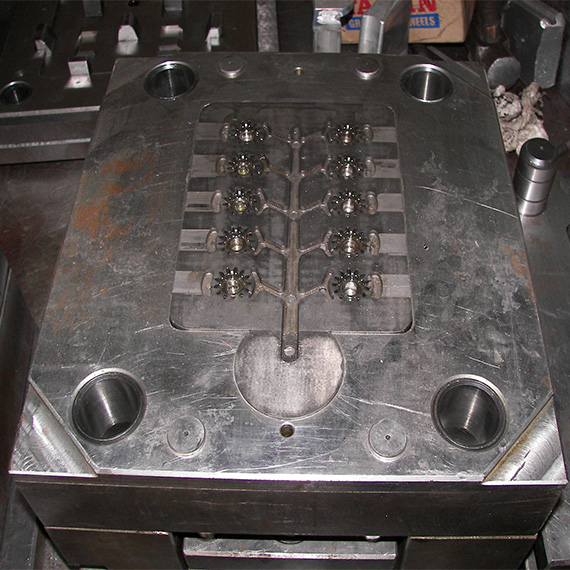

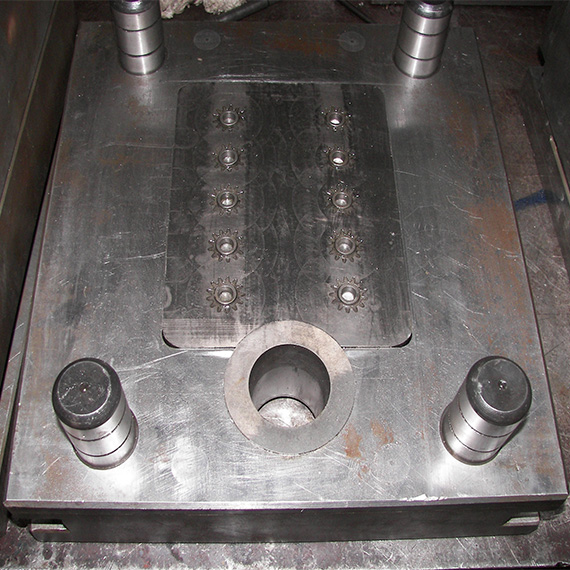

Pressure Die Casting Dies For Aluminum & Zinc & Brass

High-pressure die casting is a versatile manufacturing process in which a die casting machine uses considerable pressure to inject molten metal into a steel mold or die cavity to form products. These molds or dies can produce complex shapes with exceptional accuracy and repeatability. High-pressure die castings are extremely durable, have excellent electrical and mechanical properties, and are cost effective. Die castings are among the highest volume, mass-produced items manufactured by the metalworking industry.

Rheocast specializes in cold chamber aluminum and brass die casting. In cold chamber die casting, a precise amount of molten metal is fed into a 'cold chamber' where a hydraulic plunger forces the metal into a sealed die at high pressures.

High-pressure die casting is the preferred manufacturing process for low-cost, high-specification components with complex shapes. These include aluminum and brass components in many industries such as plumbing, hardware, automotive and agriculture. High-pressure die casting excels in producing intricate shapes with repeatability, durability and dependable quality.

- Address :

- Srinivasa Kalyana Mantapa,Hongasandra Begur Main Road,Bengaluru - 560068